New equipment for dialysis department

The process of hemodialysis uses an artificial kidney to remove toxins and excess fluids from the blood through a semi-permeable membrane. During treatment, the patient is in contact with 350 liters of water, including dialysates containing necessary substances.

It is essential that these solutions meet strict standards of quality and physical-chemical purity, particularly for electrolyte composition and the presence of contaminants. Maximum microbiological purity of dialysis fluid is crucial to the well-being of hemodialysis patients, according to studies that highlight its importance.

MDG offers consulting and analysis for water treatment applications using chemicals. These applications include sanitary circuits, steam plants, cooling and heating circuits, reverse osmosis plants, ultrafiltration, and wastewater purification. Continuous control and monitoring are essential, and MDG is committed to providing these services with professionalism and expertise in collaboration with end users in facilities.

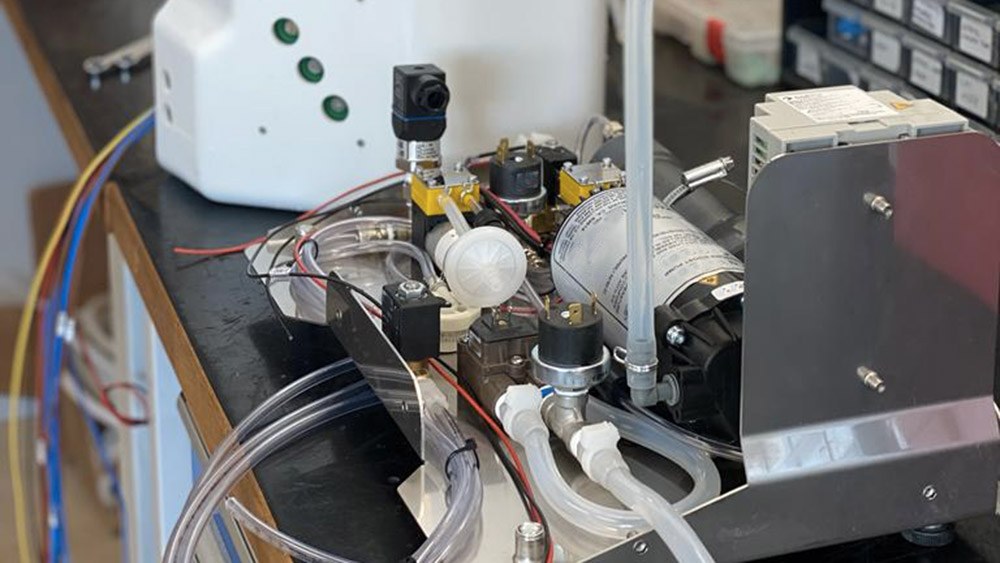

Plant installation at Tuscan hospital facility.